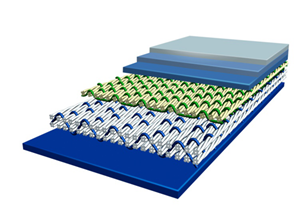

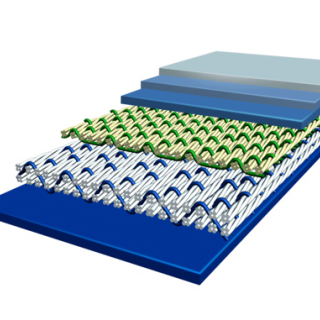

It has the characteristics of stable structure, superior compression resistance, strong continuous dehydration ability, high strength, smooth carpet surface, not easy to deform, and long service life.

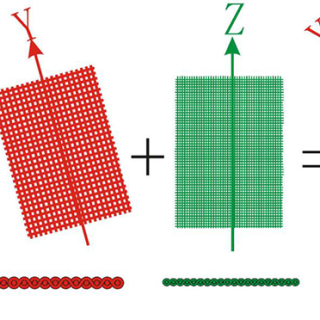

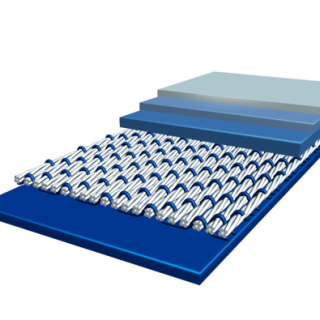

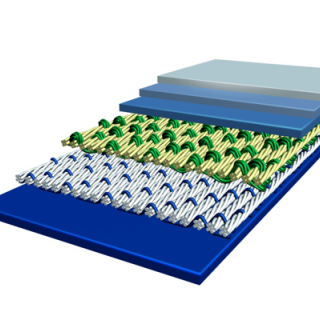

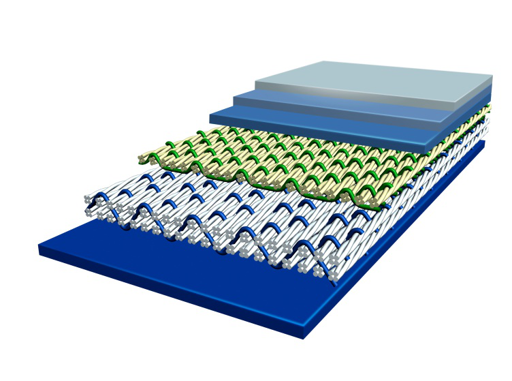

Laminated bottom wire papermaking blankets are usually divided into various base wire laminate structures such as 1+1, 1+2, 1+1+1, etc. The laminated structure can be the same or different, and the combination and matching forms are flexible, which can meet the requirements of vacuum pressing, compound pressing, etc. Large roller diameter press, shoe press and other pressing types are used to make various paper types such as packaging paper, cultural paper, special paper and so on.

The structure of the base web and the base web can be the same or different, and the combination and matching forms are flexible, which can meet various pressing types such as vacuum pressing, compound pressing, large roller diameter pressing, and shoe pressing, etc., and can be used to make packaging paper, cultural paper, special paper, etc. Paper type.

The pressure resistance of this series of blankets can reach 1000kn/m, the working speed is 300-1000mpm, and the blanket weight range is 1200-1900gsm. It has the characteristics of stable structure, superior compression resistance, strong continuous dehydration ability, high strength, smooth carpet surface, not easy to deform, and long service life.