Multi-wing block design, no entanglement, mild pulse, clean slurry, high pulse frequency, and large production capacity;

Medium-concentration screening (Max. 4%) reduces water consumption in the production process and has obvious energy-saving effects. The screen drum area is small and the investment and maintenance costs are low for the same production capacity.

The screening area is less thickened, the screening efficiency is high, and the screen drum has a long life.

Equipped with an automatic oiling device and a mechanical seal water flow monitoring device, with reserved DCS interface (bearing temperature rise and vibration detection), it has a high degree of automation.

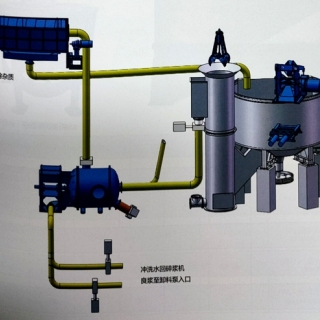

D-type pulper is mainly used for pulping various waste paper, shredded paper and cardboard in a continuous or intermittent manner according to needs. The continuous pulping system removes impurities in a timely manner, requires only a very short downtime for cleaning, and has high pulping efficiency.

The vat body is welded by stainless steel, the top of vat has a conical opening to avoid stock from splashing.

The lower steel flange connects with transmission part. there are guiding plates installed at the bottom of vat to form recirculation when stock backflow, reject channel and reject outlet are cocated in the bottom.

Below the vat is transmission device, which is main shaft, bearing, bearing base, belt pulley and so on.

Below the rotor is screen plate, it can select holes of different sizes according to customer needs.

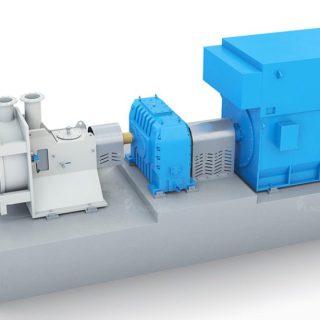

Double Disc Refiner

Double Disc Refiner is is a relatively ideal continuous pulping system at present. As required by pulping process, paper factories may choose a single set or several sets for parallel operation or series operation

inquiry

Advantages

Specially designed rotary disc is self aligned automatically under the function of stock.

According to refining requirement, clearance is adjustable through electromechanical device.

Special tool for easy and fast change of refiner disc.

High strength welded structure to ensure stable and reliable operation.

The loosening force on the fiber is relatively gentle, maintaining the physical properties of the fiber to the maximum extent.

The disintegration residence time is long, the fiber is fully decomposed, and the good fiber loss rate is less than or equal to 0.8%.

Lower power consumption reduces operating costs. There are basically no wearing parts and it can run continuously 24 hours a day without stopping, reducing maintenance costs.

Advantages

Designed on basis of hydrodynamics theory, lower motor power, more energy saving.

Optimized rotor and screen basket design makes fiber sufficiently fluidized thus higher screening efficiency.

Module design, stable and reliable structure, saving labor and time for installation and maintenance.

Equipped with automatic oiling device and mechanical sealing water flow detection device, DCS interface reserved (detection of temperature rise and vibration of bearing), high degree of automation.

lt is mainly used for deaning and thickening the stock in low consistency.

lmprove the productioncapacity and fine pulp quality.

Used for screening the pulp in chest before refiner toremove hard impurity such as iron wire and sand toavoid hard impurity to damage discThe basket is special design to isolate bulk hardimpurities in stocklnflow structural design, fixed vane inside the basket toreduce abrasion.

No packing seal or mechnical seal required in the upperdrive device, which will reduce maintenance cost.

Combined screening separate heavy reject and light rejecteffectively, which will improve efficiency.Light reject that above the liquid level is spun off bycentrifugal force, which is high dry degree and less fiber losslt is combination of Defibering, screening and dehydrationcleaning production, high fiber yield

Efficient screening to reduce fiber loss.

Designed with washing water to recover fiber efficiently.

Modular design, low maintenance cost.