Multi-wing block design, no entanglement, mild pulse, clean slurry, high pulse frequency, and large production capacity;

Medium-concentration screening (Max. 4%) reduces water consumption in the production process and has obvious energy-saving effects. The screen drum area is small and the investment and maintenance costs are low for the same production capacity.

The screening area is less thickened, the screening efficiency is high, and the screen drum has a long life.

Equipped with an automatic oiling device and a mechanical seal water flow monitoring device, with reserved DCS interface (bearing temperature rise and vibration detection), it has a high degree of automation.

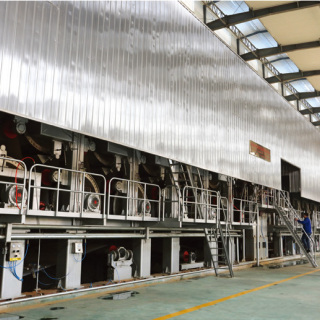

Structural principles

The pressure screen consists of a body, a cover, a screen drum, a rotary drum, a base, and a transmission part. All parts in contact with the slurry are made of stainless steel.

The pressure screen has a vertical structure, a cylindrical shell, and a removable top cover on the top. All necessary connecting pipe flanges are installed on the outer shell. The screen body and motor frame are fixed on the base by bolts. There is a circular screen drum inside, and a rotor and bearings are installed inside the screen drum. The main shaft of the screen is sealed by a mechanical seal.

The pipe end bracket is located closest to the frame. Connect the sealing water and bearing lubrication to the seals and bearings respectively.

1. Shell part

The main body of this machine is made of welded stainless steel plates. There is an annular seat inside to install the screen drum. The transmission bearing is installed on the bottom plate of the casing. There is a slurry inlet pipe in the tangential direction on the upper part and a good slurry outlet pipe on the lower part. There are slag discharge pipes and dilution water pipes at the bottom, and the entire shell is fixed on the base with bolts.

2. Top cover

The top cover is a stainless steel ball-shaped head, which is connected to the shell with bolts. The central part is equipped with a valve joint to discharge residual gas and possible light impurities in the machine.

3. Screen drum

The screen drum has two structural forms: plate type corrugated screen drum and rod type corrugated screen drum.

The screen plate of the plate-type corrugated screen drum is made of stainless steel plate and has two types: hole type and slot type. There are corrugated grooves on the surface of the sieve plate that is in contact with the slurry. Its function is to enable the fibers to easily pass through the sieve holes (slits) and effectively separate the qualified fibers from impurities and fiber clusters, thus improving the screening efficiency and obtaining high quality. of pulp. The screen plate is drilled or milled and surface polished. The screen drum has a high surface finish. A reinforcing ring is welded to the outer surface of the screen drum to make the screen drum have sufficient strength and rigidity. There is a flange on the upper end surface and is fixed to the cylinder with bolts. The upper and lower ends are located in the cylinder, and the combination is firm and the operation is stable.

The structure of the rod-type corrugated screen drum is composed of hundreds of special wedge-shaped rods, which are evenly embedded in the grooves on the circumference of the multi-layer annular plate along the circumferential direction. The upper end is a flange surface connected to the cylinder, and the lower end is a cone. body, the surface of the screen drum is wavy, the screen seams can be more refined than the plate-type milled seam structure, the precision is higher, the opening rate is significantly increased, and the rod strength is greatly improved compared to the milled seam screen plate, especially after the surface is hardened , the screen drum has a longer service life and is an advanced structural form in the world today.

4. Rotary drum

The drum is a cylinder with a number of reasonably arranged bumps on its outer surface. High-frequency pulses are generated during high-speed rotation to screen the pulp and purify the screen holes.

The rotor shaft is sealed by a mechanical seal. In order to prevent the slurry from leaking or entering the transmission chamber, this machine is equipped with a mechanical seal and a sealed water pipe interface. The water pressure is required to be about 0.1Mpa higher than the slurry inlet pressure.

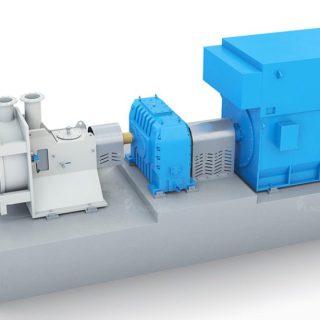

5.Driving device

The rotor shaft is supported on the bearing seat and driven by the motor through a set of narrow V-shaped belts. The lubrication device is installed on the base of the frame to lubricate the bearings regularly.

中浓筛

产品简介:

ZNS型中浓筛是现代国际广泛应用的纸浆筛选设备,是本公司吸收国际技术,研制开发的新一代纸浆中浓筛选设备。适用于木浆或草浆的热筛选;化学浆、废纸浆的粗筛选或精筛选;预热木片磨木浆的筛选等,中浓压力筛较一般低浓压力筛具有适应性强、节能、节水和生产效率高等特点。

7*24小时免费咨询热线

0371-62586186