The loosening force on the fiber is relatively gentle, maintaining the physical properties of the fiber to the maximum extent.

The disintegration residence time is long, the fiber is fully decomposed, and the good fiber loss rate is less than or equal to 0.8%.

Lower power consumption reduces operating costs. There are basically no wearing parts and it can run continuously 24 hours a day without stopping, reducing maintenance costs.

A single machine can perform continuous crushing and preliminary rough screening, simplifying the subsequent purification and separation process.

The loosening force on the fiber is relatively gentle, maintaining the physical properties of the fiber to the maximum extent.

The disintegration residence time is long, the fiber is fully decomposed, and the good fiber loss rate is less than or equal to 0.8%.

Lower power consumption reduces operating costs. There are basically no wearing parts and it can run continuously 24 hours a day without stopping, reducing maintenance costs.

The impurity crushing rate is low and the slag discharge efficiency is high, which reduces the burden of subsequent processes.

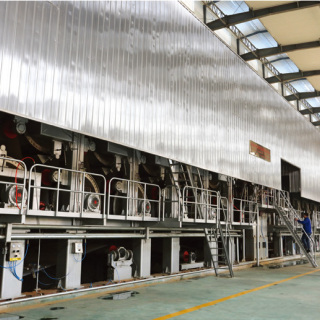

Structural principles

The machine has a roller-shaped drum with simple structure and novel design. It consists of an upper hopper, a drum, a transmission device, a supporting wheel device, a wheel blocking device, a sealing device, a guard and a slurry tank. The outer wall of the drum is inlaid with two large supporting wheels and a large gear. The two large supporting wheels are supported by two sets of small supporting wheels respectively, and can rotate on the small supporting wheels. There are a set of wheel blocking devices on both sides of the large supporting wheel on the pulp discharge side to prevent the axial displacement of the drum. The large gear on the outer wall of the drum is driven by the small gear of the transmission device to rotate the drum. The front part of the drum is the pulping area, and the rear part is the screening area. The feed port of the pulping area and the upper hopper are connected by a sealing device. The upper hopper is equipped with water and medicine inlet pipes; the screening area has a protective cover, dilution water and a slurry pool. The waste paper enters the drum from the upper hopper, passes through the pulping area and enters the pulp tank in the screening area, and the impurities are discharged from the slag discharge port.

The dilution water comes from the water spray pipe installed on the upper part of the drum. It is sprayed from the outside to the inside through the sieve plate at the top of the drum. This can backwash the fibers blocking the screen holes back into the drum, cleaning the screen holes and flushing away impurities. Adhesive fibers on.

| 型号 | ZDG250 | ZDG275 | ZDG300 | ZDG325 | ZDG350 | ZDG375 | ZDG400 | ZDG425 |

| 直径:(mm) | Φ2500 | Φ2750 | Φ3000 | Φ3250 | Φ3500 | Φ3750 | Φ4000 | Φ4250 |

| 产能:(T/D) | 70-120 | 140-200 | 200-300 | 300-400 | 400-550 | 550-720 | 750-1000 | 1000-1400 |

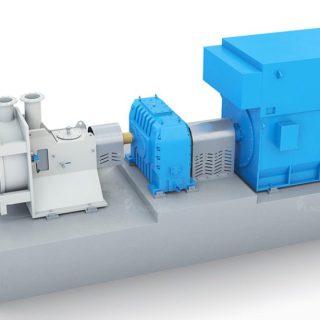

| ZDGA型电机功率:(kW) | 110 | 160 | 250 | 315 | 560 | 630 | 800 | 1000 |

| ZDGB型电机功率:(kW) | 132 | 200 | 315 | 400 | 630 | 800 | 1000 | 1250 |