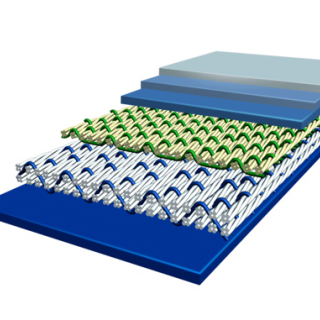

The pressure resistance of this series of felts can reach 1300KN /M, the working speed can reach1500MPM, and the gram weight of felts can reach 2000GSM. The utility model has the advantagesof stable structure, excellent compressive performance, strong continuous dehydration ability, highstrength, flat felt surface, not easy to deform, long service life, etc.

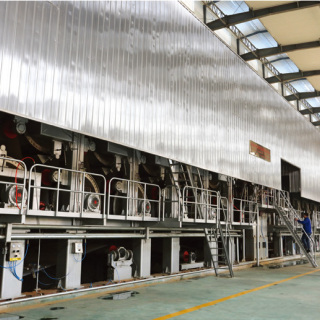

BOM papermaking felt can meet the needs of various medium and high-speed papermachines. According to the suitable paper types, it can be divided into packaging paper felt,cultural paper felt, special paper felt, household paper felt, etc.

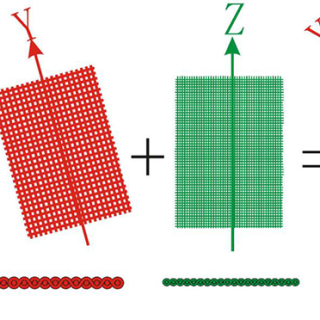

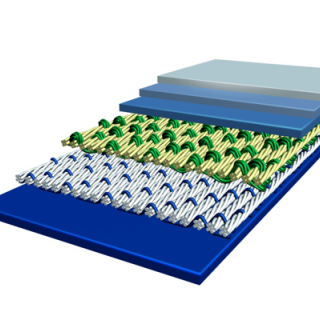

The structure of the base web and the base web can be the same or different, and the combination and matching forms are flexible, which can meet various pressing types such as vacuum pressing, compound pressing, large roller diameter pressing, and shoe pressing, etc., and can be used to make packaging paper, cultural paper, special paper, etc. Paper type.

It has the characteristics of stable structure, superior compression resistance, strong continuous dehydration ability, high strength, smooth carpet surface, not easy to deform, and long service life.

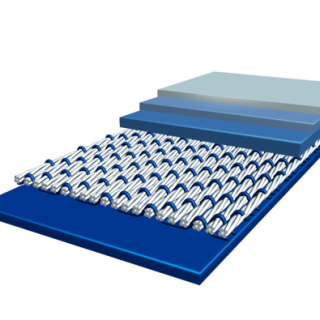

The pressure resistance of this series of blankets can reach 1000kn/m, the working speed is 300-1000mpm, and the blanket weight range is 1200-1900gsm. It has the characteristics of stable structure, superior compression resistance, strong continuous dehydration ability, high strength, smooth carpet surface, not easy to deform, and long service life.

lt has the characteristics of smooth and fine felt surface, no web mark on paper surface,reasonable flocking ratio, fi and firm combination of fibers, stable dimension, high airpermeability, uneasy hair removal, hair loss, wear resistance, anti-aging and long service life.

CONVENIENCE: Put on the felt according to the running direction, and select theappropriate space and position to faciitate the insertion of the felt.SAFETY: No need to move any press roller, felt guide roll and fixed support device, soas to avoid the potential safety hazard of conventional felt replacement.HIGH EFFICIENCY: Compared with the conventional felt replacement, it can save atleast half of the time and reach the normal operation state quickly.

This product adopts ring weaving technology, with stable structure and smooth and finefelt surface. lt can prevent the special requirements such as fuzzing and depilation offelt surface through a variety of post-processing processes.

It has the characteristics of smooth carpet surface, good pressure resistance, high strength, good dehydration, easy cleaning, and long service life.

The pressure resistance of this series of felts can reach 1300KN /M, the working speed can reach1500MPM, and the gram weight of felts can reach 2000GSM. The utility model has the advantagesof stable structure, excellent compressive performance, strong continuous dehydration ability, highstrength, flat felt surface, not easy to deform, long service life, etc.

The laminated structure can be the same or different, and the combination and matching forms are flexible, which can meet the requirements of vacuum pressing, compound pressing, etc. Large roller diameter press, shoe press and other pressing types are used to make various paper types such as packaging paper, cultural paper, special paper and so on.

The pressure resistance of this series of blankets can reach 1200kn/m, the working speed is 400-1200mpm, and the blanket weight range is 1200-2000gsm. It has the characteristics of stable structure, superior compression resistance, strong continuous dehydration ability, high strength, smooth carpet surface, not easy to deform, and long service life.