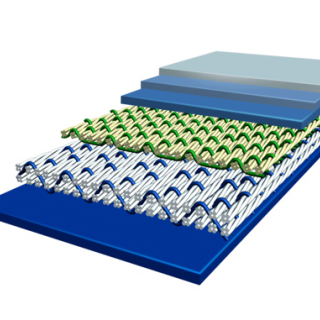

The pressure resistance of this series of felts can reach 1300KN /M, the working speed can reach1500MPM, and the gram weight of felts can reach 2000GSM. The utility model has the advantagesof stable structure, excellent compressive performance, strong continuous dehydration ability, highstrength, flat felt surface, not easy to deform, long service life, etc.

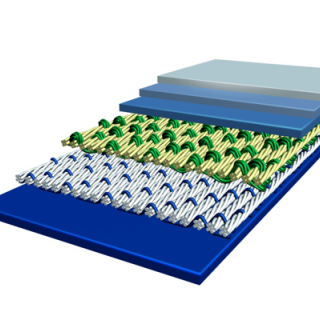

3D MULTI AXIS LAMINATED BOM FELT

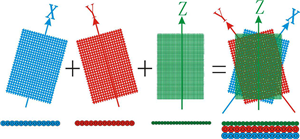

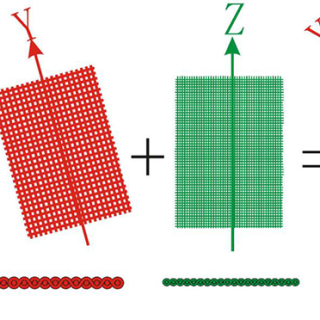

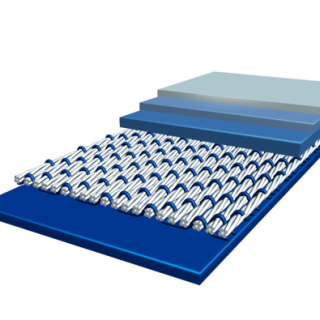

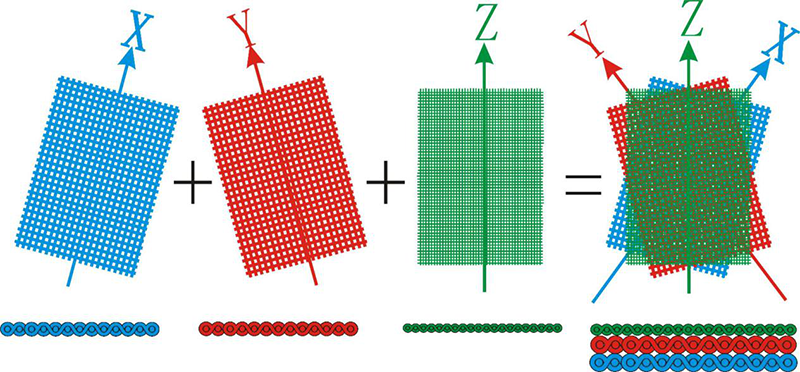

The warp and weft lines of the base mesh in the third generation papermaking felt are all vertical.Under the condition of high line pressure, the mesh and the mesh will be embedded in each other.which greatly reduces the pressure resistance and water holding space of the felt. The felt is easy toharden, the ability of continuous dehydration is weak, and the service life will be shortened.In the fourth generation of BOM, the warp and weft of the 3D multi axial laminated BOM are notwoven in a traditional 90 degree cross, but in a special angle. According to the needs of the papermachine, the mesh layer of the felt can be stacked into various foms such as X + Y or X + Y + Z, sothat the warp and weft lines of each layer of the mesh are not likely to be pressed into each otherafter overlapping, so it has higher resistance to high line pressure, faster acceleration and lowersteam consumption.

The pressure resistance of this series of felts can reach 1300KN /M, the working speed can reach1500MPM, and the gram weight of felts can reach 2000GSM. The utility model has the advantagesof stable structure, excellent compressive performance, strong continuous dehydration ability, highstrength, flat felt surface, not easy to deform, long service life, etc.