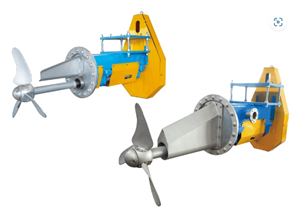

It occupies a small area, is easy to install and has low power.

Outstanding advantages

The blade design is advanced, the thrust is strong, and the angle can be adjusted according to different concentrations and pulp types, so it has a wide range of applications;

Mechanical seal form can be used;

The slurry is stirred evenly and the unit energy consumption is low.

Structural principles

It is mainly composed of six parts: impeller, transmission unit, packing seal unit, belt drive unit, frame unit, mounting ring and protective cover.

1. Impeller

It consists of an impeller seat, a blade and a ball head cover. The blades and the impeller seat are connected by positioning pins and bolts. By adjusting the combination of the positioning pin holes, the blade angle can be adjusted.

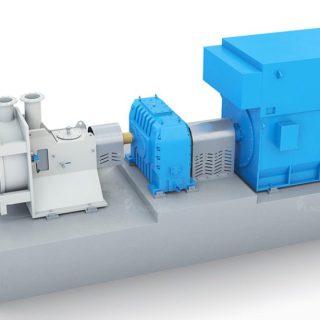

2. Transmission unit

It consists of bearing seat, bearing, main shaft, shaft sleeve, water throwing ring and spacer sleeve. The bearing seat and bearing support the main shaft. The bushing is fitted to the corresponding packing of the main shaft to protect the main shaft. The spacer bush is fitted to the part where the main shaft extends into the slurry pool to prevent corrosion of the main shaft.

3. Packing sealing unit

It consists of packing chamber, packing, water distribution ring, gasket and gland. The gasket can only be removed when replacing the packing with slurry, and the packing can be replaced by tightening the packing chamber.

4. Belt drive unit

It consists of motor, motor pulley, main engine pulley, V-belt, motor bottom plate and screw. The motor transmits power to the spindle via a belt.

5. Rack unit

It is made of square tube and steel plate welded together. It is used to fix the bearing seat and the screw of the belt drive unit, and the front flange is connected to the mounting ring.

6. Installation ring

The installation rings are divided into steel slurry pool installation rings and cement slurry pool installation rings. If the slurry tank is made of steel, use the former one; if the slurry tank is made of cement, use the latter one.

7. Protective cover

It is welded by screen hole plate and bending plate, and is used to protect the pulley and main shaft.

| 型号 | FJB600 | FJB800 | FJB1000 | FJB1300 | FJB1600 |

| 叶片直径:(mm) | 600 | 800 | 1000 | 1300 | 1600 |

| 浆料浓度:(%) | ≤4.5 | ||||

| 浆池容积:(m³) | 20-50 | 50-80 | 80-120 | 100-150 | 150-250 |

| 电机功率:(KW) | 5.5-11 | 5.5-15 | 11-30 | 30-55 | 55-90 |