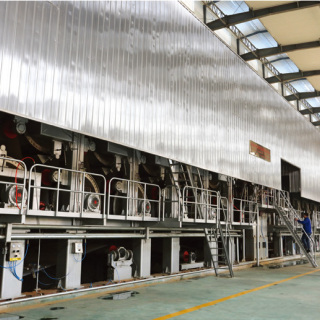

The BFW chain plate conveyor is mainly used to transport various bulk or bundled materials in the papermaking industry. It can be used for horizontal transportation or transportation with an inclination of less than 30°. It is mostly used for feeding waste paper and pulp boards to the pulper.

Structural principles

The chain plate conveyor consists of five parts: the head driving device, the tail wheel device, the tensioning device, the chain plate and the frame.

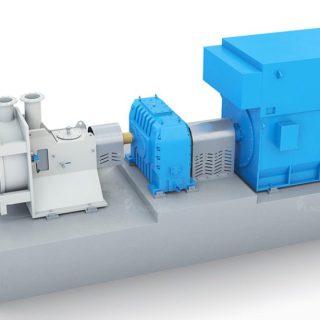

head drive

It is composed of motor, reducer, transmission device and driving sprocket device. The power is transmitted from the driving device to the main shaft through a pair of sleeve roller sprockets, which then drives the groove plate to run. The driving sprocket device uses two sprockets with 6 teeth to drive two piece traction chains and groove plates to run along the guide rail.

Tail wheel device

The redirection part of the chain plate of the machine consists of the tail wheel shaft, two tail wheels and bearings.

tensioning device

The tensioning device adopts a spiral tensioning method to adjust the tightness of the traction chain.

Chain plate part

Composed of traction chain and groove plate. The traction chain adopts an impact-resistant, smooth and reliable piece-type traction chain. A roller is installed in the middle of the inner chain piece and rolls on the track to reduce friction resistance and wear. The groove plate is fastened with bolts and traction chain.

frame

It consists of head frame, tail frame and middle frame. It is welded with channel steel, angle steel and reinforced steel plate. There are four tracks in the middle of the frame for the rollers to run, which are made of light rails.