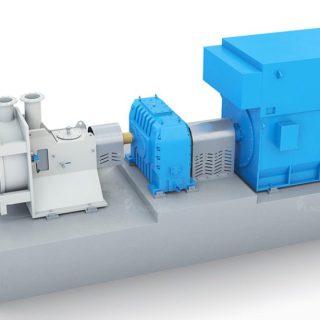

HD Cleaner

HD cleaner is used in a high concentration to remove paper pulp in a larger share of the metal,sand, and various kinds of heavy impurity to get high quality pulp of a kind of ideal equipment, also is the necessary equipment for the purification of waste paper pulping.

inquiry

Advantages

Big sight window for easy visual inspection of vortex and control

Long separating cone and small taper angle, high cleaning efficiency.

Working consistency is from 2%-5%

Special fast open discharging control valve, sufficient reject, easy operation.

Wear resistance ceramic cone, long service lifetime.

Working Principle

HD cleaner is the use of fibers and impurities in different proportions to separate the impurities .The slurry at a certain pressure from feed three tangent enter slag separator before high rotation speed, due to the different centrifugal force, heavy impurity is thrown to the wall .under the action of gravity, gradually to the bottom of the cone operation, into the sediment cans. Because of small centrifugal force, Fiber gradually run into the center the low pressure area, to scroll up after the bottom, and finally discharge by good pulp mouth .A high concentration of removing the dregs device in addition to with certain taper cone, and the cone is long, pulp in the cone in decreasing the rotation radius, avoid pulp flowing in the process of reducing speed, ensure that the centrifugal force is strengthened, and improve the efficiency of purification for paper .The bottom water pressure balance is slightly bigger than pulp pressure, so that fiber can't go into the tank bottom, only sand ,metal particles, glue, piece of plastic ,and other heavy impurity sink into the pot, reducing the loss of fiber.

Technical Data

Model ZCS3B ZCS4B ZCS5B ZCS6B Output(L/min) 3000-4600 4500-5800 6000-7500 9000-12000 Inlet Consistency (%) 2-5 Inlet Pressure (MPa) 0.3-0.35 RejectingType Automatic

HD series

Model HD3 HD4 HD5 HD6 HD7 HD8 Throughput: (L/Min) 1300-1700 1700-2500 2500-3200 3000-4500 4500-6000 6000-8000 Feed pulp consistency:(%) 2-5 Feed pulp pressure(MPa) 0.3-0.4 Pressure difference: (MPa) 0.12-0.15 Reject Discharge method Continuous or intermittent automatic